The Curious Case of Energy Meter Spikes

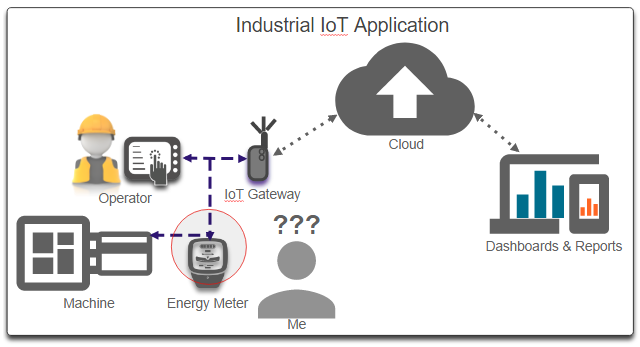

The Industrial IoT field is a very interesting one. You can never guess when and how an issue in one area might lead to investigating and solving problems in a completely new area. One such learning happened with me when I was working on a project in Africa, which involved installing energy meters for every machine in the plant.

An energy meter was connected to a machine at a client facility to calculate the energy consumption of the machine for advanced analytics. All was going good until I noticed that the energy consumption recorded on the energy meters was on the opposite side of zero. This sent us on a frenzy of rigorous testing and investigation to identify the problem.

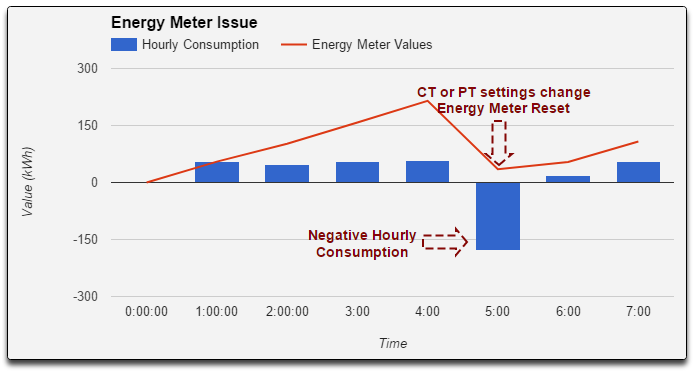

The energy consumption during a specific time period is normally the difference of the energy meter value at the end of the period and the value at the start of the period. But, I was not aware of the limitation of the energy meter that if the CT and PT settings were changed, the counter would reset back to zero and hence the difference would result in huge negative figures of consumption. During our field commissioning we were changing CT and PT values regularly and the whole energy analytics of the plant was going haywire.

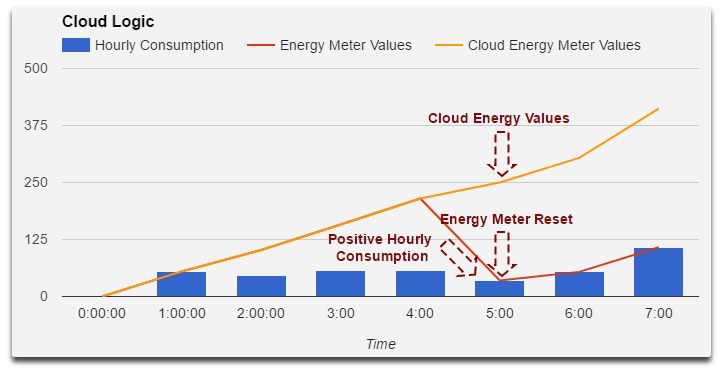

After some brainstorming, we came up with a fix for this issues – every time the energy meter’s value was reset to zero we implemented logic to detect this reset on the cloud, where the energy meter data was being stored every 1 minute, and then added the new energy meter values to the stored energy meter value on the cloud.

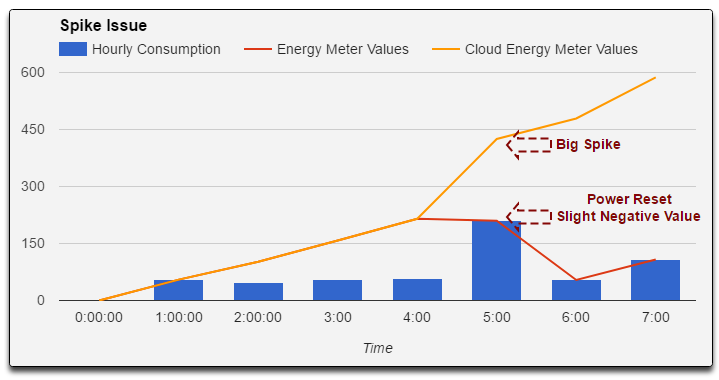

Problem solved right? Wish that was true! After the first problem was solved, another one crept in, this time even worse. The energy consumption was on the positive side, but we could observe spikes in energy meter values which were too high to be acceptable. Imagine if a machine consumes more energy in an hour than the rest of the year!

It was another weekend wasted in the field to investigate this issue. We went through every piece of paperwork with a fine-tooth comb, and also roped in the energy meter providers to uncover the problem. After two days of investigation, we found that the energy meters were programmed to record the consumption reading at a 40 second interval and store it in the built-in flash memory.

Every time there was an interruption in power, the latest energy meter reading would be lost, and hence the last stored value would be used for calculations. As per the logic implemented by us, the latest consumption value would be checked against the previous one, if the latest value is below the last stored value we would add the new value to the last stored value. Since the previous value was smaller, it was directly added into the latest figure and hence a spike would occur. This was further proven by checking and interrupt counter which recorded a spike for every instance of interruption.

Finally, the energy meter manufacturer were told about the issue and they ensured that all new energy meters are sold after fixing this issue. Apparently even the energy meter manufacturer were unaware about the fact that this small logic issue can have a major impact on the customer in the world of big data analytics.

We still had to use old energy meters and were successful in adding a logic on the cloud before processing the data for energy consumption analytics. It was a great learning curve for the myself and my team and I am confident that such an event will not occur again in the future.

Selecting an energy meter, without this issue, for all our industrial IoT applications is an important purchase criteria for myself and my team.

Thank you for reading this article. I am Bhavesh Deulkar and I am an engineering lead at EcoAxis.