The Ministry of New and Renewable Energy is encouraging the use of solar energy, as solar energy is the most abundantly available form of renewable energy. Use of solar energy which is a renewable energy source aids in peak load shaving and conservation of electricity, fossil fuels. It is a clean, non-polluting form of energy that can be utilized for all thermal energy applications. To promote use of solar energy, Government of India and other international bodies have different programmes/ projects to provide subsidies and financial support to the user .

Since the onset of the program, a major barrier towards growth in the number of installations and the capacity utilization has been the lack of awareness among industries regarding the technologies available for using solar energy in their facilities. Hence we have taken this step of contributing to the progress of the solar based applications and thus to impact the life on the planet, by generating awareness among the industries as to which technologies are available to harness solar energy and which is the best suited technology for their industry. Concentrating Solar Technologies are used to harness solar for thermal applications where the temperature requirement is higher than 80.

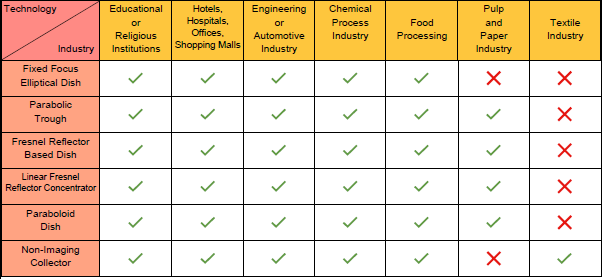

A mapping chart of CST technologies with individual industries is given below:

Each CST technology is explained in brief in sections below.

1. Fixed Focus Elliptical Dish (FFED) – Scheffler

FFEDs (commonly called Scheffler dish) is the most common technology used to solar harness for available across the globe, including India owing to the availability of multiple manufacturers, resulting in quick availability and low cost. The technology involves a fixed focus receiver on which the solar rays are concentrated using an elliptical dish of mirrors to ensure the maximum rays of the sun are reflected to the receiver to harness heat. Scheffler dishes have a an average efficiency rating of 52% at 120⁰C and find applications in majority of industries.

2. Parabolic Trough Concentrator (PTC)

PTC is a mature technology which involves a linear parabolic reflector that reflects the sun rays to receiver placed along the focal line. The concentration of solar rays allows the heat transfer fluid to reach fluid temperatures of up to 400⁰C, making it a technology which can be used in the power generation industry. It is low on maintenance and high on efficiency up to peak efficiency of 80% at 120⁰C, albeit certain challenges such as limited manufacturers in India and variation in efficiency based on the time of the year.

3. Fresnel Reflector Based Dish (FD)

FDs are large sized reflectors made of flat surface mirrors arranged in a fresnel arrangement to concentrate the solar radiation on a cavity receiver. They are equipped to track the movement of the sun and thus always facing the sun to gain the maximum efficiency which measures to 82% at 110⁰C. FDs can heat up water or thermic fluids to a temperature of up to 350 degrees Celsius, and also have a low footprint in terms of area. A major challenge for FDs is the limited manufacturing owing to less players, resulting in longer wait times for deliveries. FDs find applications in varied industrial segments, including dairy, textile, community cooking, etc .

4. Linear Fresnel Reflector Concentrator (LFRC)

LFRCs are line focus concentrators with long mirrors arranged in linear fresnel arrangement to focus the incident sun rays to a single focal line where the receiver is placed to that convert the solar energy to useful form of thermal energy. LFRCs are used for their ability to generate high fluid temperatures of up to 400⁰C with a decent efficiency rating of up to 65% at 120⁰C. Limited number of manufacturers of LFRCs across India is a major hurdle for the growth in adaptation of the technology owing to high wait periods and cost. In terms of applications, LFRCs find applications in majority industries, thermal power plants included.

5. Paraboloid Dish

Solar concentrators shaped in the form of a parabola are called parabolic dish concentrators. The dish concentrates the incident solar rays to a receiver which is capable of high density concentration, allowing fluids to reach a temperature of 400⁰C with an average efficiency rating of 60% at 120⁰C with the ability to peak up to 80%. Paraboloid dishes find applications in almost all industries.

6. Non Imaging Collector (NIC)

NIC (also known as Compound Parabolic Concentrator) is a row of evacuated tubes fitted, with each tube having two parabolic mirror segments to concentrate the incident radiation. NICs have a low concentration level, thus the obtained temperatures being on the lower side make it ideal for use majorly in the textile industry among others, and have an acceptable efficiency rating of up to 60% at 110⁰C. As there is no tracking requirement, NICs have a niche application for temperatures upto 120⁰C, which is being boosted as more industries are using NICs in their facilities mainly for boiler feed water preheating.

We are expecting that our best foot forward to generate awareness about the harnessing of solar energy through the available technologies can help industry owners make wise decisions in adopting the best suitable option at their facilities. This can go a long way in using the abundant energy resource available and contributing towards sustaining our eco system; not to mention the generous financial support and subsidies on offer by the Government of India.