‘LEED’ing the way: A.T.E.’s facilities receive LEED Gold awards!

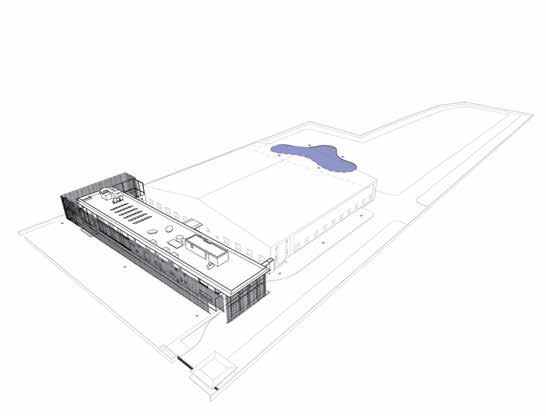

A.T.E’s efforts in going green were rewarded when it was awarded the Leadership in Energy and Environmental Design (LEED) Gold certification from the Indian Green Building Council (IGBC) for both its A.T.E.-EcoAxis-HMX integrated facility at Bhosari, Pune, and its TeraSpin , manufacturing facility and office at Sari, Ahmedabad. These facilities include offices, factories, and a laboratory.

LEED is the IGBC’s leading rating system also a world-standard developed by USGBC for designing and constructing the greenest, most energy efficient, and high performing buildings; A.T.E.’s facilities were designed in compliance with LEED Gold standards for eco-friendly practices in planning, design, and construction. This is the second-highest level of certification possible.

According to Mr Anuj Bhagwati, Head, A.T.E. Group, this ties in nicely with A.T.E.’s commitment to the triple bottom line of people, planet, and profit: “A.T.E. lives by values of sustainability, care, commitment, openness and innovation. We are a group that creates products and technologies – and this requires us to have our own laboratories, assembly and manufacturing spaces, and collaborative offices.”

Careful attention was paid to all aspects of the design and construction process of both sites to reduce the impact on the surrounding environments – beginning with the design of the building, the initial stages of construction, and the completion of the project. Specific areas of focus were the design and sourcing of sustainable materials and resources for construction, energy and water conservation, energy-efficient comfort solutions, and indoor air quality.

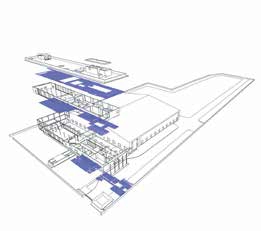

Integrated approach to design

At the same time, local conditions such as climate, site orientation, and the high water table were taken into consideration during the design phase. This integrated approach allows A.T.E.’s buildings to function more efficiently.

Sustainable construction practices

Water conservation

Energy

Energy Performance Index at A.T.E.’s facilities

Computer building energy models show that these measures help reduce energy use intensity (or EUI) by a significant amount (40% in the case of the Sari facility, from 145 kWh/m2/year to 90 kWh/m2/year). Over the last year, building performance monitoring confirmed the modeling estimates, with an achieved energy performance index (EPI) of 78 kWh/m2/year (for Sari), and 128 kWh/m2/year (Bhosari), making these facilities among the most energy efficient offices in India.

Click on the links to read more about the design, architecture, and resource efficiency of our LEED Gold certified facilities at Sari, Ahmedabad (PDF, 5.8 MB), and Bhosari, Pune (PDF, 7.2 MB).