PRODUCT

Atmoset SMT-15

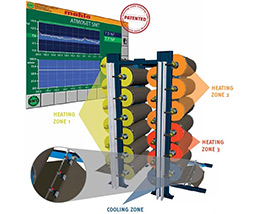

The Atmoset SMT controls the residual moisture of the fabric with steam-heated drum dryers. The key to accurate and even residual moisture is in two superposed control loops. The first control loop is used to measure and control the condensate temperatures of the drum dryers combined in groups. The deviation of the condensate temperature from a preset setpoint is used to directly calculate the amount of energy required for drying. The steam supply is adjusted to the moisture of the incoming product. The second control loop captures the residual moisture of the product after leaving the dryer, using special measuring electrodes. It supplies the pulses to adjusting the setpoint for the condensate temperature control so that the product obtains the desired residual moisture. The intelligent controller algorithms used provide for a rapid but especially stable control of the residual moisture, taking all input variables into account.

Manufactured by: Mahlo GmbH & Co. KG., Germany

-

FEATURES

-

BENEFITS

-

RESOURCES

-

GET A QUOTE

-

Key Features

- As per fabric quality and residual moisture required, only precise amounts of steam enter can dryers

- Process control loop based on condensate temperature and residual moisture

- Improved quality

- Increased process repeatability

- Intuitive user interface

- Energy saving to the tune of 20-25 percent; short amortisation time

- Easy to retrofit/install